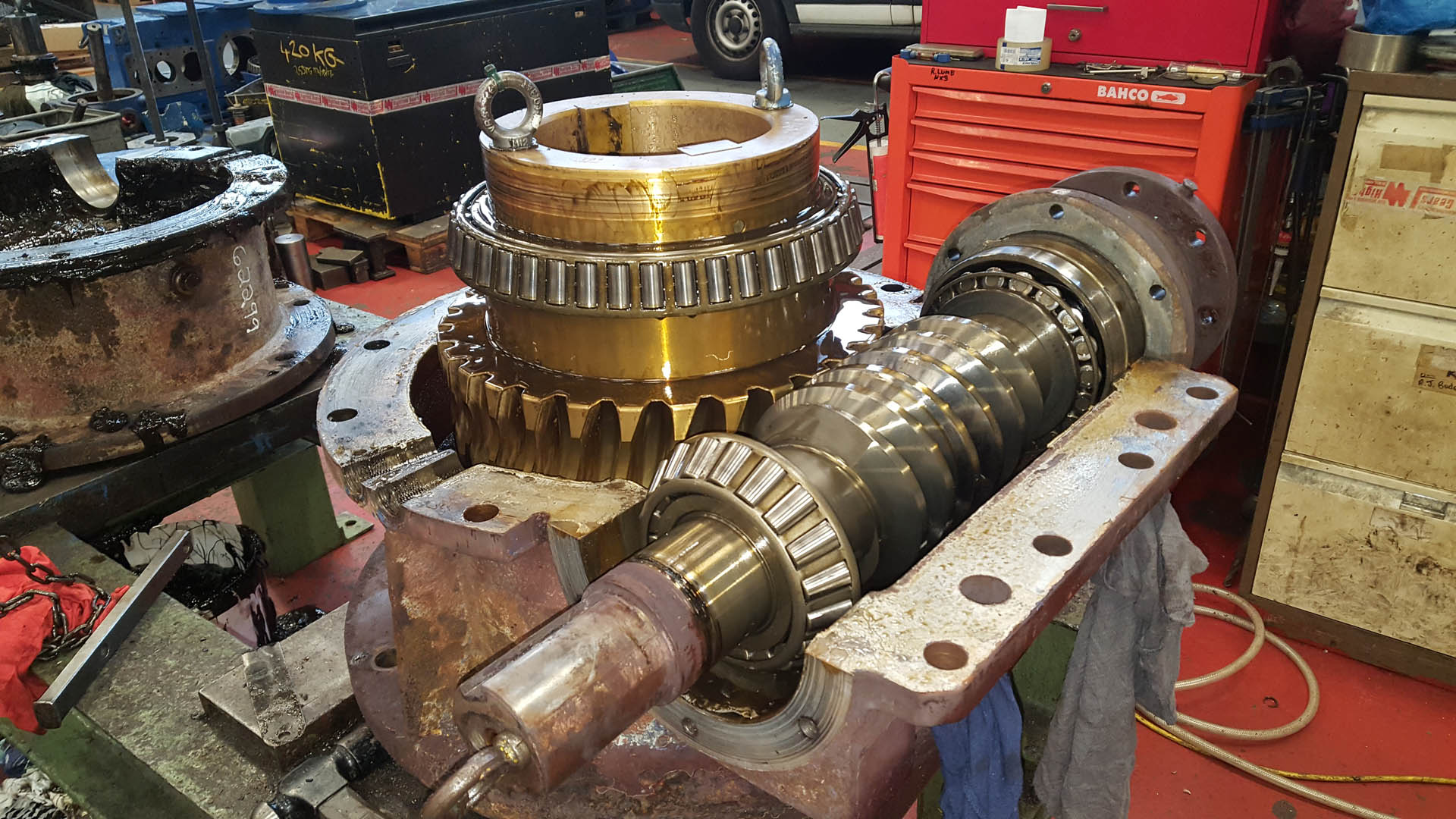

Since we were founded in 1927 we have been honing our skills and enhancing our ability to fix a wide range of industrial gearboxes.

We’re trusted by several businesses and organisations across the world, such as Dulux, Tata Steel and Heineken. They trust us to recondition gearboxes, undergo entire gearbox replacement and operate CNC machining. We’ve built this trust and grown our reputation by combining years of knowledge about gearboxes with a passion for providing impeccable customer service.

Our dynamic and flexible approach to fixing and reconditioning gearboxes allows us to respond rapidly to customer needs. We understand that gearbox issues can crop up at the most inconvenient times which is why we work around the clock, 24 hours a day 7 days a week, to ensure your gearbox gets fixed in the appropriate time.